Robert Wallner

Supervision: Univ.-Prof. Dipl.-Ing. Dr. Bernhard Zagar

Imaging techniques are playing an important role for quality management. Because of this, different physical effects have been employed for various technical measurement problems. Most of those effects could be incorporated into sensor arrays, but sometimes there are technological or financial restrictions. One solution to this problem is building a mechanical transition stage using a single sensor to generate an image. Most commercially available setups do not allow for a synchronisation of positions and measured values slowing the measurement process down.

This bachelor thesis solves this problem with a real-time Linux control system. To do this, the open-source projects RTLinux, LinuxCNC and COMEDI were combined into a measurement unit.

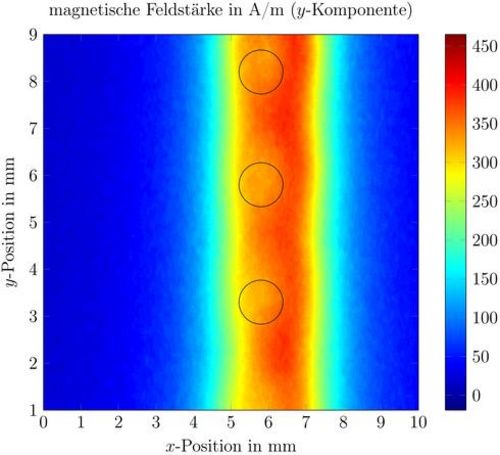

Figure 1: Magnetic field values of a strip board supplied with a fixed current.

Figure 1: Magnetic field values of a strip board supplied with a fixed current.

Using a custom TCP/IP solution, data such as measured values or control input can be exchanged with a client software like Matlab.

The measurement system is able to use different kinds of sensors. To demonstrate the functionality of the system a three dimensional Hall sensor is used. With this sensor it is possible to capture the magnitude and direction of a magnetic field. This allows to find faults in conductive materials which is vital for quality management problems.

Keywords: LinuxCNC, COMEDI, real-time Linux, CNC, magnetic field, Hall-Probe

September 03, 2014

Go to JKU Homepage

Go to JKU Homepage