Thomas Altmanninger

Supervision: Univ.-Prof. Dipl.-Ing. Dr. Bernhard Zagar

Rapid-Prototyping has become a vital part in development and research in the past few years. Because of this, manufacturing electronics by rapid prototyping technologies gets more and more important. Research at the institute for Measurement Technology focuses on printing electronics via commercial inkjet printers. The standard ink-cartridge is replaced by cartridges filled with a special ink containing copper-nanoparticles for example .

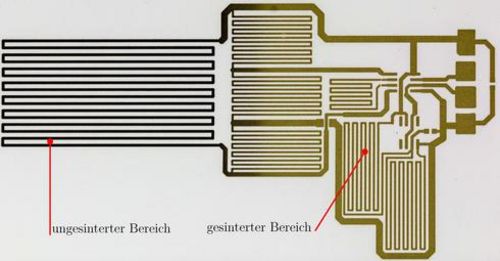

Figure 1: Printed silver-nanoparticles partially sintered.

Figure 1: Printed silver-nanoparticles partially sintered.

Because most of the printable nanoparticles are not conductive after drying off, printed electronics often need a cure in form of a sinter process. This bachelor thesis analyses the sinter process of printed electronics. Furthermore the construction of a sinter device using a xenon flashtube is shown.

Special features of the device are the adjustable operating voltage of the flashlamp and the lightimpules with an adjustable duration. The device is controlled via a microcontroller, which is linked to a computer running Matlab, which allows a comfortable use.

The device's function is demonstrated by results of several carried out sinterpocesses using silver-nanoparticles and copper-nanoparticles. The process of flashlight-sintering is especially suitable for nanopraticles with high melting temperature, where other processes like thermal-sintering reach failure.

Keywords: printed electronics, flashlight-sintering, nanoparticles, xenon-flashtube

August 09th, 2015

Go to JKU Homepage

Go to JKU Homepage