Dominik Hofer

Supervision: Univ.-Prof. Dipl.-Ing. Dr. Bernhard Zagar

The process of manufacture of thin plastic foils with a quality sufficient for optical needs is a highly complex one. One of the industrial partners of the Institute for Measurement Technology encountered problems with such a plant: the final product had chatter-marks (as shown in Figure 1). Same professors of the Johannes Kepler University Linz were asked to find a solution, but the problem remained. The Institute for Measurement Technology took first steps and tried to characterize the defects within the foil and discovered their schlieren-like behavior while testing samples off-line. In succession to these off-line measurements an appropriate measurement setup (see Figure 2) was developed to measure schlieren on-line or at least at-line. Measurements taken with this new setup rendered it possible to find the initiating cause of the chatter-marks.

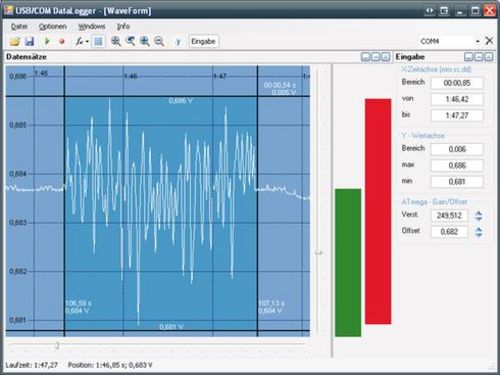

Figure 3: The frontend displays the measurement data, its mean (green) and limits (red). Display and hardware parameters may be adjusted at the right side of the picture, atop is a toolbar providing basic commands. It's possible to view the FFT on-line and to save data to Matlab Level5 mat-files.

Figure 3: The frontend displays the measurement data, its mean (green) and limits (red). Display and hardware parameters may be adjusted at the right side of the picture, atop is a toolbar providing basic commands. It's possible to view the FFT on-line and to save data to Matlab Level5 mat-files.

This work looks into schlieren and the effects on light passing through them. The schlieren-method and its application are discussed and the measurement setup is introduced. Some numerical approximations are taken to calculate diffraction patterns caused by schlieren. After a characterization of the setup by means of a spatial light modulator (SLM) some real foil-samples have been measured and the results are presented. The main task of this seminar is to depict the setup, the used electronics and the developed software programs. It acts as an operating manual for the software frontend (see Figure 3) and as a guide to its source-code. With regard to future applications some software functions, e.g. the fast-fourier-transformation, are described to use them for new purposes.

Septemeber 25, 2008

Go to JKU Homepage

Go to JKU Homepage