Analysis of, and signal processing for a subjective laser speckle-based, non-contacting strain measurement system.

Dr. Alexander Spaett M.Sc.

Supervisory committee: | |

| Univ.-Prof. Dipl.-Ing. Dr.techn. Thomas Thurner, opens an external URL in a new window | |

| Univ.-Prof. Dr. Bernhard Jakoby |

| Final exam: | April 26, 2024 |

Fiber composites are often used in high-tech products. Therefore, it is necessary to characterize the fibers from which they are made. Part of the mechanical characterization involves measuring the stress-strain curve. Due to the generally small dimensions of the fibers, accomplishing this task is challenging. In the context of this work, a system developed for strain measurement within thin fibers is analyzed, and its signal processing is optimized.

The measurement system uses subjective laser speckle patterns to determine the strain. These patterns serve as markers for the movement of local surface elements, similar to those applied when video extensometers are used. By observing the displacement of two such local surface elements of a sample before and after deformation and knowing the initial distance between the two surface elements, the engineering strain can be estimated.

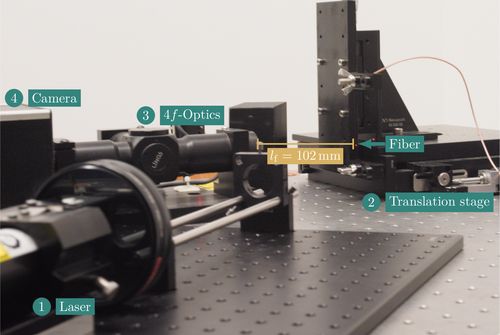

The laser speckle patterns required for this method are generated and observed using the following components: HeNe-laser, 4f-optics, and linescan camera. The measurement system is depicted in Fig. 1.

It can be shown that the size of the speckles observed by the linescan camera depends on the aperture used in the Fourier plane of the 4f-optics. An optimal speckle size for the signal processing used is justified and found through simulations. The optimal speckle size then leads to the optimal dimensions of the aperture.

In addition to the theoretical analysis of the system, it is demonstrated that the crosspower density spectrum, estimated using the Welch method, provides a good basis for estimating the displacement of local surface elements and thus the strain. Weighting similar to that used in the Generalized Cross Correlation improves the measurement result.

A summary and an outlook are given, concluding with suggestions and approaches for further future system improvements.

Fig. 1: Measurement setup: A HeNe-laser illuminates the fiber sample which is observable only with the help of the red laser dot. The scene is then imaged through a 4f-optical setup with a rectangular aperture in its Fourier plane, utilisied to achieve elongated speckles. Finally, the speckles, which are formed in the image plane, are captured by a linescan CCD camera. The captured images are then subject to further digital signal processing to get an estimate for the displacement of the local, illuminated surface area.

Fig. 1: Measurement setup: A HeNe-laser illuminates the fiber sample which is observable only with the help of the red laser dot. The scene is then imaged through a 4f-optical setup with a rectangular aperture in its Fourier plane, utilisied to achieve elongated speckles. Finally, the speckles, which are formed in the image plane, are captured by a linescan CCD camera. The captured images are then subject to further digital signal processing to get an estimate for the displacement of the local, illuminated surface area.

Keywords: laser speckle pattern, strain measurement, 4f-optics, fiber, cross spectral density, optimal speckle size

Go to JKU Homepage

Go to JKU Homepage