Supervision of Bachelor's and Master's theses

Interested in process engineering?

We offer supervision for bachelor's and master's theses in the field of process engineering.

Why a Bachelor or Master in Process Engineering? The "Young Process Engineers" created a brochure that offers an insight into the diverse and exciting tasks of a process engineer. Get more information!, opens a file (sorry, only in german available)

Inquire about current topics directly with Prof. Hlawitschka mark.hlawitschka(at)jku.at.

BACHELOR

Recycle lithium-ion batteries

Lithium-ion batteries have become an indispensable part of our everyday lives. At the end of their service life, the batteries can be used as a secondary source of raw materials. In addition to lithium, the elements cobalt and nickel are of particular interest. They are found in the active material of the rechargeable battery. Using chemical processes, the metals are first broken down and separated hydrometallurgically.

We offer bachelor theses on the following topics:

Recycling of lithium-ion batteries on a pilot scale extraction column

MASTER

Electrolysis of lithium-ion batteries

Aim of the thesis

The aim of this work is to set up and commission a trainer for investigating the electrolysis of active material. The trainer will be used to investigate parameters such as voltage, current intensity and current density on the yield of metals (Li, Co, Mn, Ni).

Task in Detail

- Construction of a trainer for the electrolysis of lithium-ion batteries

- First examination of operating parameters

- Voltage

- Acid concentration

- Validation of the test results

- Optimization of the test stand

Contact

Supervisor: Dr.-Ing. Alexander Keller

If you are interested please contact the supervisor.

BACHELOR / MASTER

Currently we are looking for a student to perform and extend various Computational Fluid Dynamics (CFD) simulations with previous experience in programming or the interest to learn programming (C++). The goal is to describe process engineering phenomena such as coalescence and phase transition. The description of these phenomena is relevant to accurately describe and design stirred tanks, separators as well as various reactors. The implementation of the phenomena is done in an open source code (OpenFOAM). The work can be done directly at the PCs of the institute, but also as home work.

Please contact: Mark Hlawitschka

![[Translate to Englisch:] Apparatur](/fileadmin/_processed_/8/1/csm_Bild_Apparat_ba1ece2f6f.jpg)

MASTER

Why it matters: Carbon dioxide emissions are a major driver for global climate change. Capturing and reusing CO2 can help mitigate its impact and transform it into resource. Our research focuses on optimizing bubble column technology for this purpose.

Research Highlights:

- Efficient CO2 Absorption: We investigate how bubble columns facilitate the absorption of CO2 into liquid solutions, studying parameters like gas holdup and bubble size.

- Scalable Solutions: By simulating and designing custom reactors, we ensure our systems are adaptable for industrial applications.

- NaOH-Based Capture: Using sodium hydroxide solutions, we analyse reaction kinetics, pH changes and mass transfer rate to improve capture efficiency.

- Simulation and Design: Gas disperser systems are the heart of the bubble column and are easy adaptable.

Student opportunities:

Design and optimize your own dispersers (3D printing), test them in pilot-scale plants, and analyse reaction data. If particularly interested, you can also investigate the modelling of CO₂ mass transfer.

MASTER

Why it matters: As demand for lithium skyrockets with the rise of renewable energy storage, developing environmentally friendly ways to recover lithium is crucial. We explore innovative methods to extract lithium carbonate using industrial by-products.

Research Highlights:

- Sustainable Lithium Recovery: Lithium sulphate solutions react with CO2 in our bubble column systems, precipitating high-purity lithium carbonate.

- Integrated Processes: We design and test disperser to optimize gas-liquid interactions, enhancing reaction efficiency.

- Product Refinement: Recovered materials are processed further to obtain higher yield and purity (Battery production grade).

Student opportunities:

Execution of reaction processes on a pilot-scale. Study reaction efficiencies, develop and optimize experiments. If particularly interested, you can also explore the modelling of precipitation processes.

MASTER

Why it matters: Per- and Polyfluoroalkyl (PFAs), known as “forever chemicals”, are hazardous pollutants found in water systems worldwide. Removing them requires innovative techniques that balance effectiveness and environmental safety.

Research Highlights:

- Flotation Technology: Using reactor teststations, we design and test 3D-printed Venturi nozzles to generate fine bubble for flotation of PFAS to the surface.

- Safe Testing Approaches: We work with polymer-analog to simulate PFAs behaviour, ensuring safety during experiments.

- Industry Collaboration: By combining experimental data with machine learning, we refine designs for scalability and industrial application.

Student opportunities:

Test nozzle geometries, analyze bubble behavior, and optimize flotation processes. Compare small-scale test setups with real industrial plants. If particularly interested, you can also investigate the modeling of jet nozzle processes

![[Translate to Englisch:] Blasenverhalten](/fileadmin/_processed_/d/4/csm_Bild1_886d638379.png)

MASTER

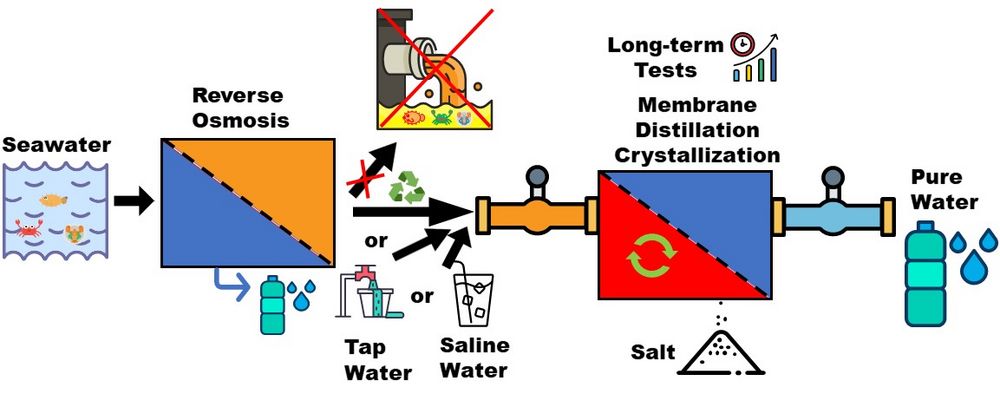

Desalination via membrane destillation

Membrane distillation for desalination is an attractive research topic worldwide.

This technology for water treatment, especially for desalination of seawater and highly saline industrial waste streams using low-carbon energy sources, such as low-carbon waste heat or solar energy.

A topic of the future!

Tasks:

- Scientific processing of the membrane distillation crystallisation project (MDC).

- Carrying out investigations on fractional crystallisation and characterisation of NaCl, CaCO3 and MgSO4.

- Investigate nucleation and growth kinetics in the presence of seeds in AGMDC.

- Determination of suitable operating conditions to control the shape, size, size distribution and polymorphism of crystals in a metastable concentration/temperature zone.

- Set-up of the MDC facility.

- Extensive measurements at the MDC facility.

You are also welcome to develop a research topic (e.g. for a student research project or doctoral thesis).

For further information, please contact Prof. Mark Hlawitschka.

Illustration of a membrane distillation plant for desalination

Illustration of a membrane distillation plant for desalination

Go to JKU Homepage

Go to JKU Homepage