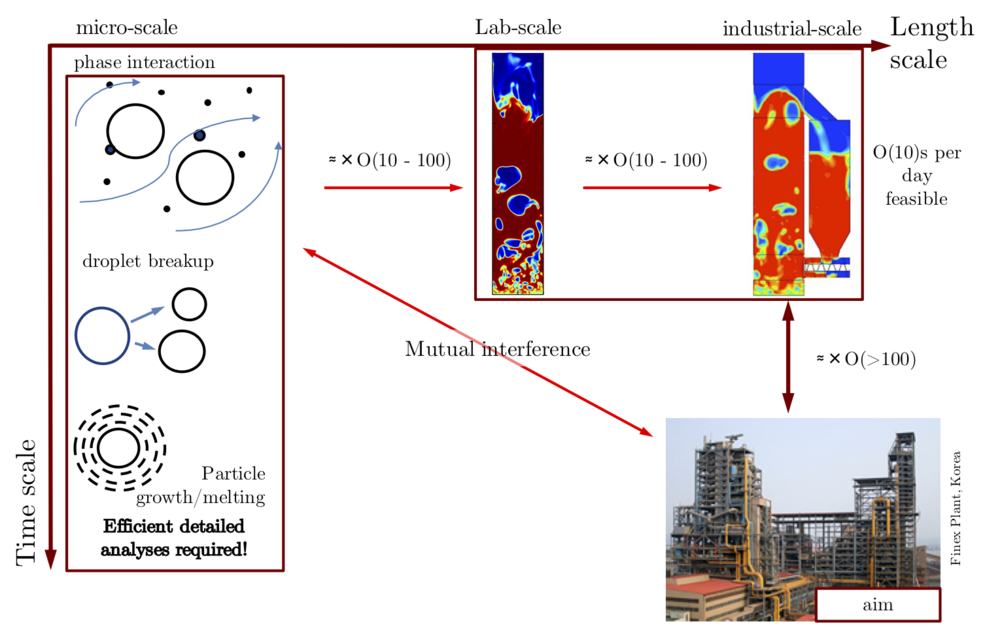

Our research focus aims at pioneering novel multi-scale simulation methodologies to enable the numerical analysis of long-term large scale gas-solid processes, based on a systematic concurrently connected coarse-graining that analyses different temporal and spatial scales simultaneously.

In many industrial processes multiphase flows, which consist of multiple separate yet interacting phases, are of primary importance and multi-scale modeling is essential to gain a deeper understanding of these processes at large (industrial) scales. Here, many relevant multiphase flows are made up of a continuous primary phase (gas, liquid) and dispersed secondary phases (solid particles, liquid droplets, bubbles). State-of-the-art multi-scale modeling methods consider the different spatial length scales separated and temporally disconnected. These methods further ignore the wide range of the involved temporal scales. Above that the characteristic time scale of the real process may be in the range of hours requiring unaffordable high computational resources and in general the coarse grained models depend on the microscopic properties of the actual system (e.g. particle clusters and small scale design features).

Our multi-scale approach consists of:

-

a magnification lens concept, where small scale features can be included simultaneously in an efficient coarse-grained simulation without requiring expensive separate fine-grid simulations (read more...);

-

macrostructure dependent sub-grid models by establishing the idea of “cluster turbulence” leading to considerably more general sub-grid corrections (read more...);

-

a temporally coarse-grained model rendering the analysis of long-term industrial-scale multiphase processes accessible by using the rCFD method – here, we expect that the computational efficiency will be improved by at least three orders of magnitude (read more...).

Finally, the above multi-scale modeling strategies will be supported by analytical as well as experimental investigations, which will serve as verification and validation sources in addition to existing literature.

This CD-Laboratory is installed at the Department of Particulate Flow Modelling at the Johannes Kepler University/Linz. At the beginning we will start with three industrial partners (Borealis AG, Primetals Technologies GmbH and voestalpine Stahl Linz) and will apply the above multi-scale methodologies to a) Industrial Emulsification and (b) Metallurgical Processes.

The outcomes of this CD-Laboratory will not only yield new and highly valuable insights on the nature of large-scale multiphase flows but will also considerably enhance the numerical analysis of the long-term industrial processes. This is especially of high relevance and of vital importance for the industrial partners of this CD-Laboratory. Finally, we further expect considerable impact of the proposed multi-scale methodology on the numerical simulation of environmental flows and life sciences.

Zur JKU Startseite

Zur JKU Startseite